US Building of the Week

Gemma Observatory

Anmahian Winton Architects

7. August 2017

Photo: Anmahian Winton Architects + Client (All images courtesy of v2com)

The winner of an AIA Small Project Award, an AZ Award (for under 1,000m2), and an American Architecture Award, Anmahian Winton Architects' Gemma Observatory is a striking building whose form is rooted in its rocky surroundings and conceals a highly sustainable, net-zero structure with a unique purpose. Alex Anmahian answered a few questions about the project.

Location: Central New Hampshire, USA

Architect: Anmahian Winton Architects

Principals: Alex Anmahian AIA, Nick Winton AIA

Project Manager: Mazen Sakr

Project Team: Anika Gramsey, Travis Williams

General Contractor: Patriots Builders - Scott Estabrooks

Structural Engineer: RSE, Associates, Inc. - Sofya Auren P.E.

Technical Motion Engineer: Gillespie Corp.

Rotating Rail Mechanism: THK

Metal Installer: Crocker Architectural Sheet Metal Co., Inc.

Steel: Quinn Brothers Iron Works

Structural Insulated Panels: Foard Panels Inc.

Decorative Steel: Concentric Fabrication LLC - Rob Lorenson; Tresfort Metal Works - Pierre Tresfort

Solar Panel Design: SunBug Solar

Photo: Anmahian Winton Architects + Client

What were the circumstances of receiving the commission for this project?

AW was one of several architects interviewed by the owner for the project. As we understand it, the owner formed a list through personal research into the work of various firms and through recommendations from the heads of architecture schools at various universities. The selection process was an informal interview with the owner.

Photo: Anmahian Winton Architects + Client

Please provide an overview of the project.

This private astronomical observatory is located on a remote mountain summit in central New Hampshire. The site is characterized by granite outcroppings and is situated at the center of a three-mile radius “dark” landscape with very little light pollution to obstruct astronomical viewing.

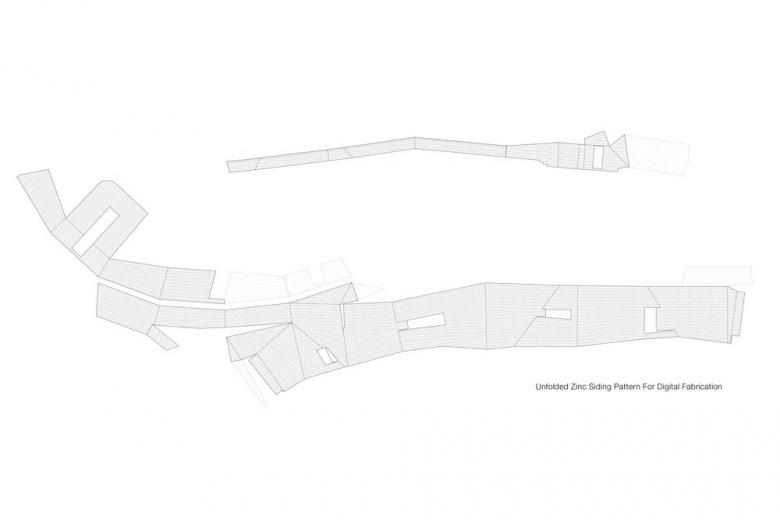

Gemma’s design rejects a traditional dome in favor of a synthesized architectural form that maximizes usable space and responds to the stark geographic context. Its continuously faceted shape reflects the surrounding landform, and terraced concrete platforms transition between the summit’s bedrock and the building foundation, knitting together natural and man-made landscapes. An unconventional pattern of lock-seamed zinc cladding mediates between the irregular site topography and the building’s geometry, reflecting Gemma’s orientation to both geological and celestial landmarks. Its dimension, color, and patina evoke a material relationship to the gray granite outcroppings, while its heat transfer capability facilitates sky observation by minimizing temperature differential distortion.

Photo: Anmahian Winton Architects + Client

As a counterpoint to the exterior and its context, the interior is lined with fir plywood, creating a haven of refuge and warmth from the harsh surroundings. The first floor is comprised of a research office, sleeping bunk, and warming room, and is super-insulated to prevent interior/exterior temperature differentials from creating heat eddies that would impede astronomical viewing. A helical stair leads from the cantilevered entry canopy to a fissure in the cladding that opens onto the exterior observation deck. Continuing, the stair arrives at the observatory’s primary viewing platform inside the faceted turret, its interior characterized by high ceilings, a larger telescope, and a camera array. A single person can rotate this turret by hand with an assembly typically used in high-precision manufacturing facilities, and a hand-cranked sliding hatch opens the telescope to the sky. A rift in the zinc cladding creates a corner window, framing Polaris when the turret is locked into the southern cardinal position.

Photo: Anmahian Winton Architects + Client

How does the design respond to the unique qualities of the site?

Gemma Observatory is molded by its surroundings, integrating environmental, geological, and celestial influences into a nexus connecting earth and sky. Its terraced concrete walkway emerges from the summit’s granite outcroppings, while its continuously faceted shape is expressed an extension of the site’s landform. Patterned zinc cladding integrates the site’s irregular topography with the building’s geometry, as its dimension, color, and patina evoke a material relationship to the austere environment.

Photo: Anmahian Winton Architects + Client

How did the project change between the initial design stage and the completion of the building?

We initially approached the project with a relatively invasive meandering footprint with the intent of engaging the site by cultivating the surrounding landscape. The approach sought to create context for a tiny intervention in the otherwise untouched rugged terrain. As the design evolved — along with our understanding of the site — we reversed our approach and instead looked to the characteristics of the locus to inform the architecture. To claim its place on the hill, we drew on the abstract forms and monochromatic palette of the outcroppings at the summit to lend monumentality to the architectural object.

Photo: Anmahian Winton Architects + Client

Was the project influenced by any trends in energy-conservation, construction, or design?

Gemma Observatory, a net-zero building completely disconnected from any municipal utilities, exemplifies AW’s ethos of sustainability in design and in construction planning. A solar photovoltaic farm strategically located on the south face of the summit provides all necessary power for heating, lighting, and automated astronomical tracking for the finished building. From a planning perspective, the photovoltaic farm was constructed first to provide all power for construction of the building. In addition, the building is outfitted with a water-free composting toilet. Environmental impact to the summit is minimized with careful siting and with a foundation system that conforms directly to the underlying bedrock, thus eliminating any displacement of the natural geography. The building is constructed of high efficiency structural insulated roof and wall panels that were constructed off-site within a controlled environment and erected in only five days. Zinc cladding was chosen for its longevity and maintenance-free qualities, while responding to the programmatic need to efficiently transfer heat, thereby avoiding atmospheric distortion at the telescope lens. Construction assemblies were designed and material selections were made to ensure an unusually long life for the building—over 100 years.

Photo: Anmahian Winton Architects + Client

What products or materials have contributed to the success of the completed building?

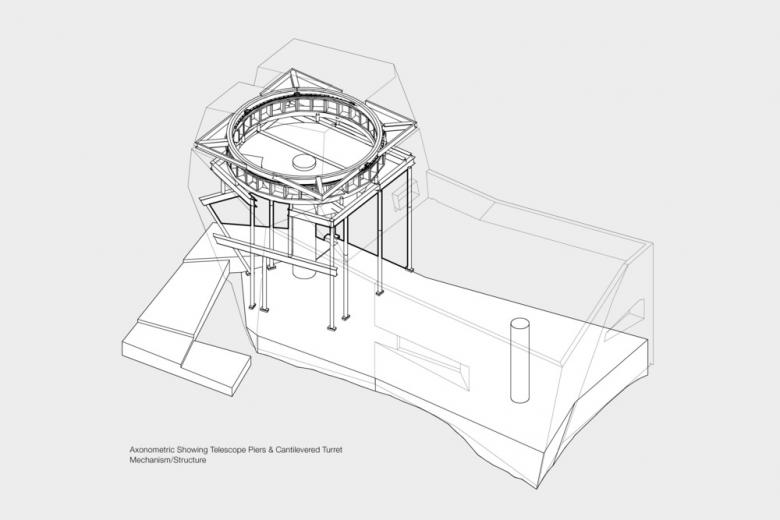

The project marries three manufacturers’/fabricators’ products to create a turret that is precise and easy to operate, and hearty enough to require virtually no maintenance. The turret components are comprised of 1) rails and roller-bearing trucks that carry the weight of the turret and are manufactured by THK; 2) an annular gear the diameter of the turret (16ft or 4.9m) fabricated by Quinn Bros of Essex, MA, and 3) a hand cranked or electrically operated gearbox that connects to the annular ring (the latter for automated celestial tracking and recording).

Email interview conducted by John Hill.

Photo: Anmahian Winton Architects + Client

Site plan (Drawing: Anmahian Winton Architects)

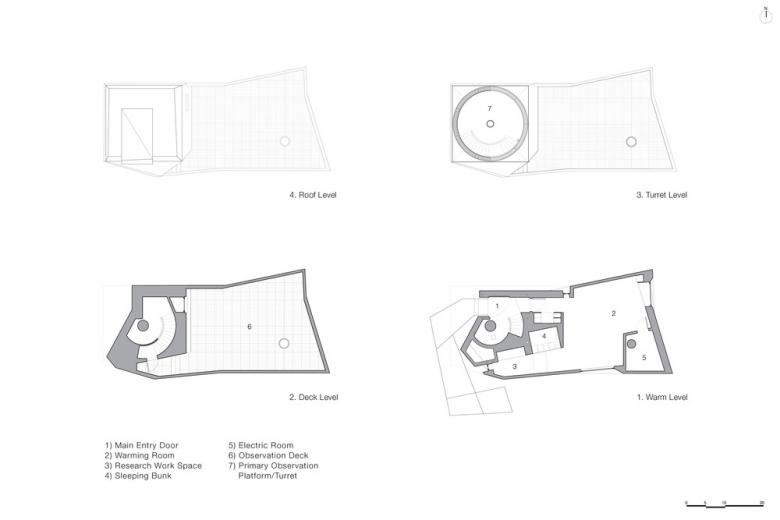

Floor plans (Drawing: Anmahian Winton Architects)

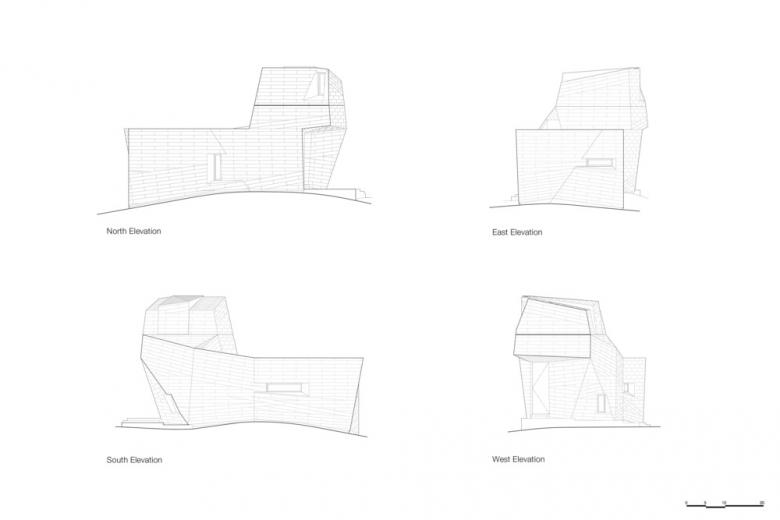

Elevations (Drawing: Anmahian Winton Architects)

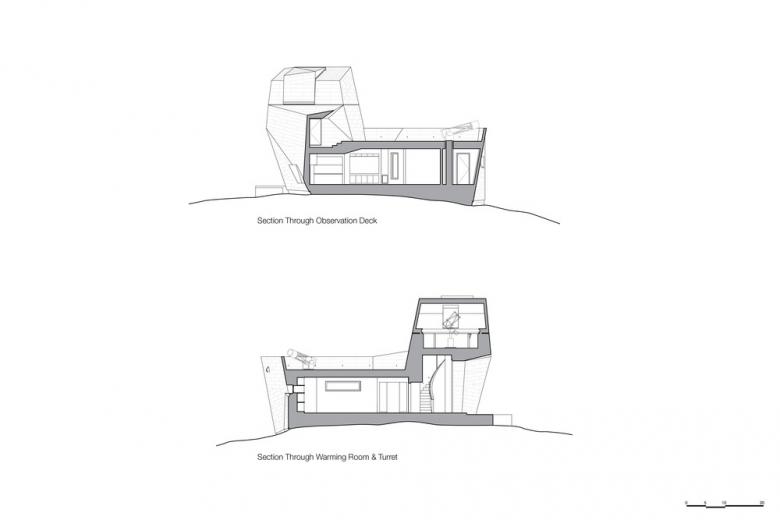

Sections (Drawing: Anmahian Winton Architects)

Axonometric showing telescope piers and cantilevered turret mechanism/structure (Drawing: Anmahian Winton Architects)

Unfolded zinc siding pattern for digital fabrication (Drawing: Anmahian Winton Architects)

Related articles

-

The History of Via Verde

on 9/6/23

-

Touring Brooklyn Tower

on 9/5/23

-

‘r kids Family Center

on 1/23/23

-

Studio Visit: Dattner Architects

on 10/18/22