U.S. Building of the Week

Lighthouse Office

Knowhow Shop LLC

14. January 2019

Photo: Stephen Schauer

Like a glowing gem amidst its dark industrial surroundings, the Lighthouse Office stands out as something special. Designed and built by L.A.'s Knowhow Shop as an office space adjacent to their workshop, the small structure can be moved about the yard or even to another site, if needed. The architects at Knowhow Shop answered a few questions about the Lighthouse Office.

Location: Los Angeles California, USA

Client: Knowhow Shop LLC

Architect: Knowhow Shop LLC

Design Principals: Kagan Taylor + Justin Rice

Contractor: Knowhow Shop LLC

Fabrication: Jake Van Vranken, Miguel Aguilar, Brandon Yount

Site Area: 1,250 sf (Shop Yard)

Building Area: 154 sf

Photography: Stephen Schauer, Nephew LA, Marisa Vitale

Photo: Nephew LA

What were the circumstances of receiving the commission for this project?

Knowhow Shop, a design/build studio located in the Los Angeles neighborhood of Highland Park, was founded in 2010 by Kagan Taylor and Justin Rice as an extension of their shared interests in traditional craft, digital fabrication, and a commitment to contemporary architectural design. Starting initially with small projects and unusual requests, Knowhow Shop has built a reputation as a laboratory for material exploration, a conservatory of both digital and traditional craft, and a community space for strange and imaginative happenings. In their own architecture and design work Justin and Kagan continue to approach projects with a craftsperson’s sensitivity, genuine good humor, and a belief that what they make can redirect the discipline from the hyper-digital to a real-surreal. We built Lighthouse as a response to our own lack of dedicated office space in our shop. As we grew and acquired new equipment and hired additional employees we saw the need for an office that was adjacent too but not inside our fabrication space. Lighthouse was our response to that. Given that we are renting, we wanted a project we could take with us; and given that we are primarily a experimental design build firm we wanted a project that could be a prototype for future buildings.

Photo: Stephen Schauer

Please provide an overview of the project.

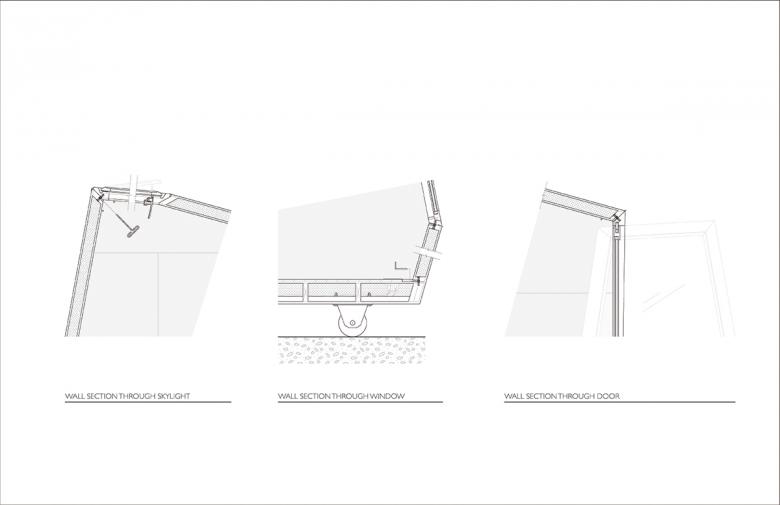

Lighthouse is a micro-building designed and built like a piece of furniture. We discarded typical details and assemblies in favor of new methods of construction from the ground up. The result is a project designed to test our craft in materials and our perceptions of space: from a door with no right angles, to a custom made skylight that marries traditional boatbuilding materials with details borrowed from a car sunroof, to shop fabricated and mitered SIPs (Structural Insulated Panels) joined with film industry hardware. This is not a project that we would have been able to hand off to a contractor to execute, so we bypassed the normal methods of architectural production and relied on the most experimental potential of our design/build model. Lighthouse is an office for our business, a showcase of our craft, and an example of the huge potential within rethinking the way we design and build.

Photo: Stephen Schauer

What are the main ideas and inspirations influencing the design of the building?

Lighthouse is named to reflect both its construction system – lightweight prefabricated panels that are assembled on site with minimal impact to the environment – and its iconic openings: a oversized and entirely custom door, window, and operable skylight that provide plenty of natural light during the day and project a warm inviting glow at night. Without the necessity of a traditional foundation, Lighthouse rests on industrial casters originally designed to support roll-off dumpsters and can be moved around the shop yard to facilitate material deliveries and flexible outdoor space. We hope that future Lighthouses will become beacons for those searching for smaller sustainable buildings that embrace contemporary architectural design.

Photo: Stephen Schauer

How does the design respond to the unique qualities of the site?

Lighthouse needed to tuck into a corner of our small shop yard, but we wanted it to be capable of more so we designed it as we would a freestanding independent building hoping that someday we would be able to move it to a more picturesque location.

Photo: Stephen Schauer

Was the project influenced by any trends in energy-conservation, construction, or design?

We drew a lot on the current interest in tiny homes but the fact that we didn’t use a trailer chassis to build Lighthouse gave us a little more flexibility with the plan and form. We developed and built an operational skylight in hopes that we would be able to use passive ventilation however the realities of the current site mean we have to keep the door closed most of the time to keep out noise and dust from the manufacturing spaces adjacent.

Photo: Stephen Schauer

What products or materials have contributed to the success of the completed building?

We built this as a prototype and so we did literally everything ourselves. But with the intention of building more Lighthouses in various configurations, we have been grateful for the help of some potential vendors for the SIPs panels and the doors and windows.

Email interview conducted by John Hill.